General Overview

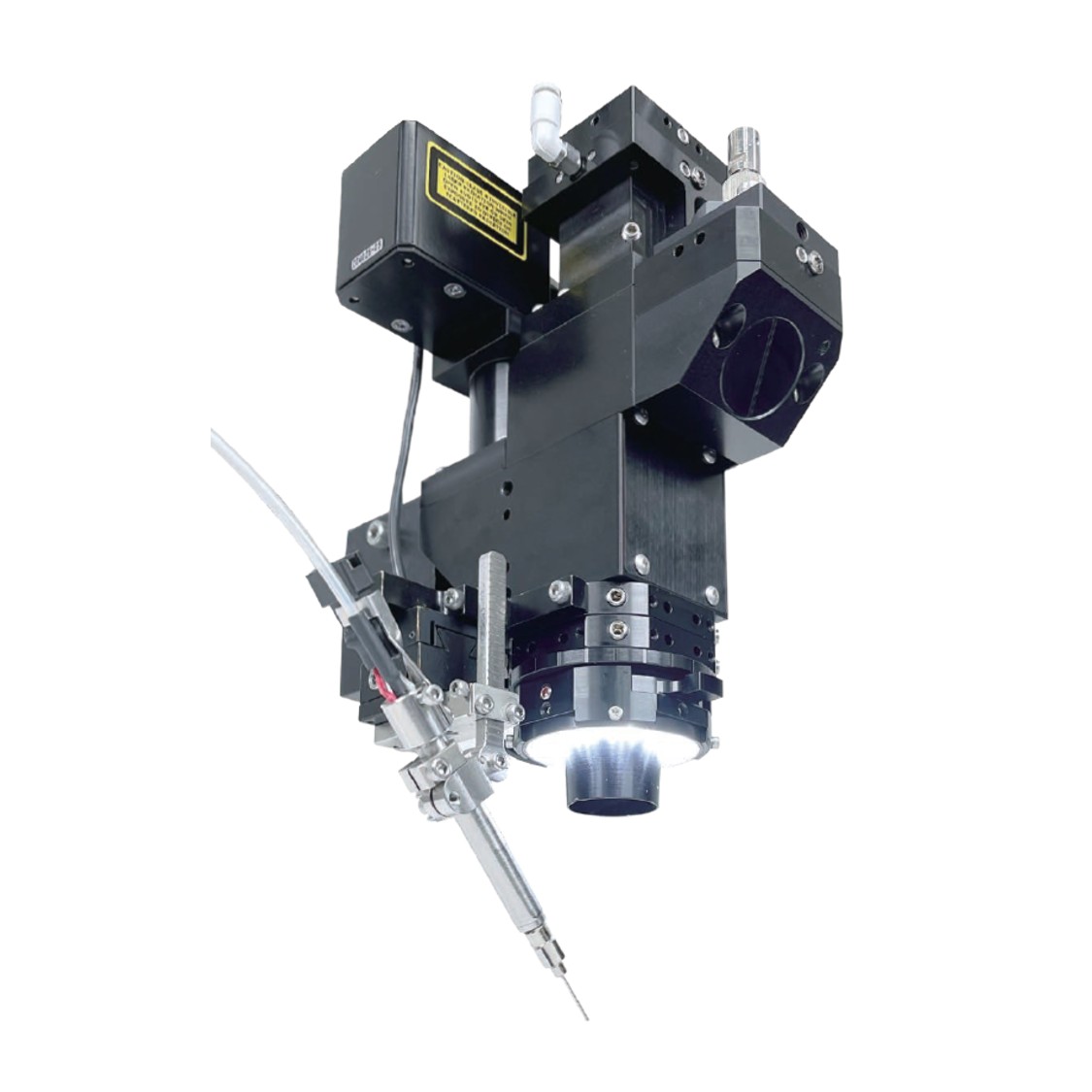

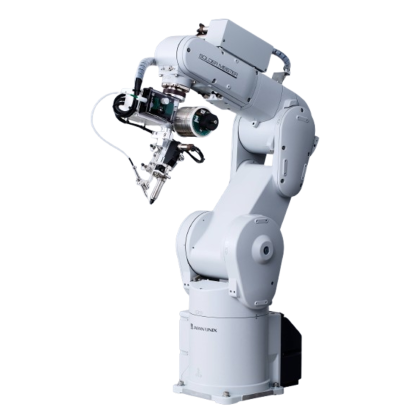

As electronic circuit boards become thinner and components more complex and multilayered, technology is advancing so rapidly that traditional soldering methods can no longer keep up. Laser soldering enables precise soldering in ultra-fine areas that are difficult or impossible to reach with conventional soldering irons.

Features

In soldering process, basically a 3 step process that encompasses pre-heating of soldering point (1), apply heat to supply the solder (2), and post-heating to shape the solder (3) and finish it. The workflow is applying same in using iron tip soldering and laser soldering, but method of heat supply to solder is differ.

In soldering process, basically a 3 step process that encompasses pre-heating of soldering point (1), apply heat to supply the solder (2), and post-heating to shape the solder (3) and finish it. The workflow is applying same in using iron tip soldering and laser soldering, but method of heat supply to solder is differ.

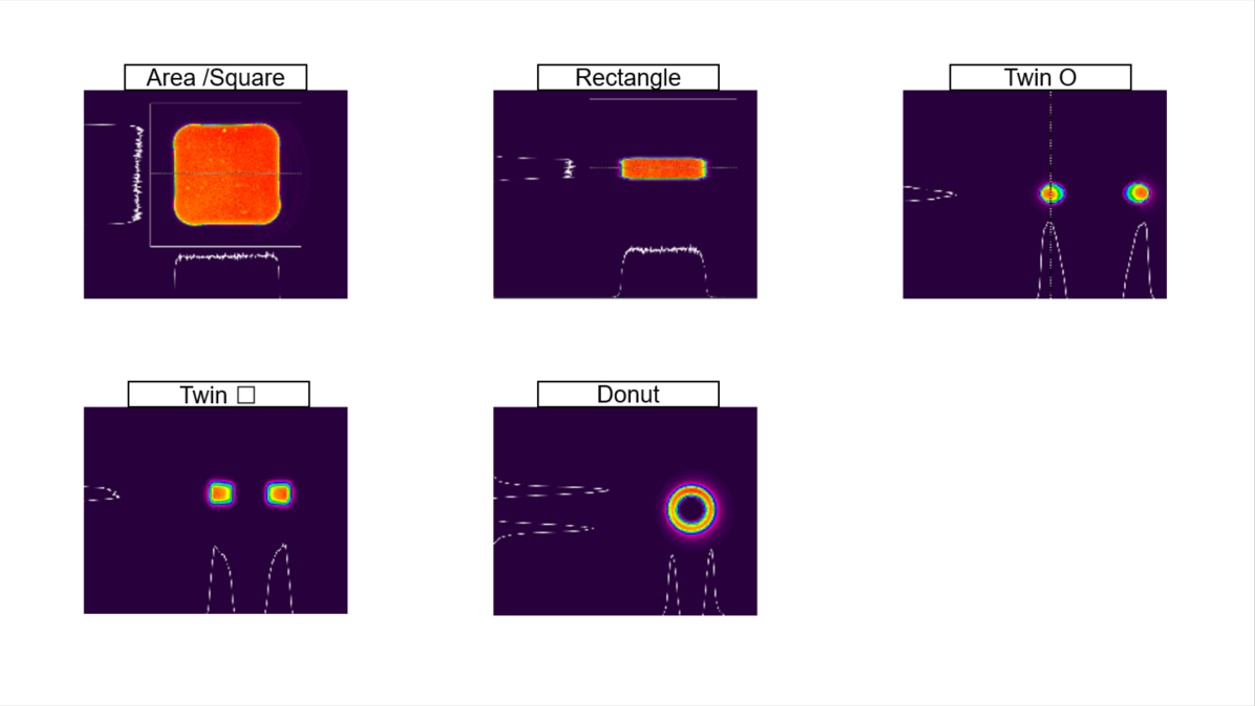

Laser shape optimize improves soldering efficiency

The optimized laser shape delivers heat efficiently and supports multiple patterns including circles, ellipses, squares, rings, and other custom shapes. The Multi-φ function allows spot size adjustment without changing the working distance (Z-axis), enabling easy optimization for different pad sizes.