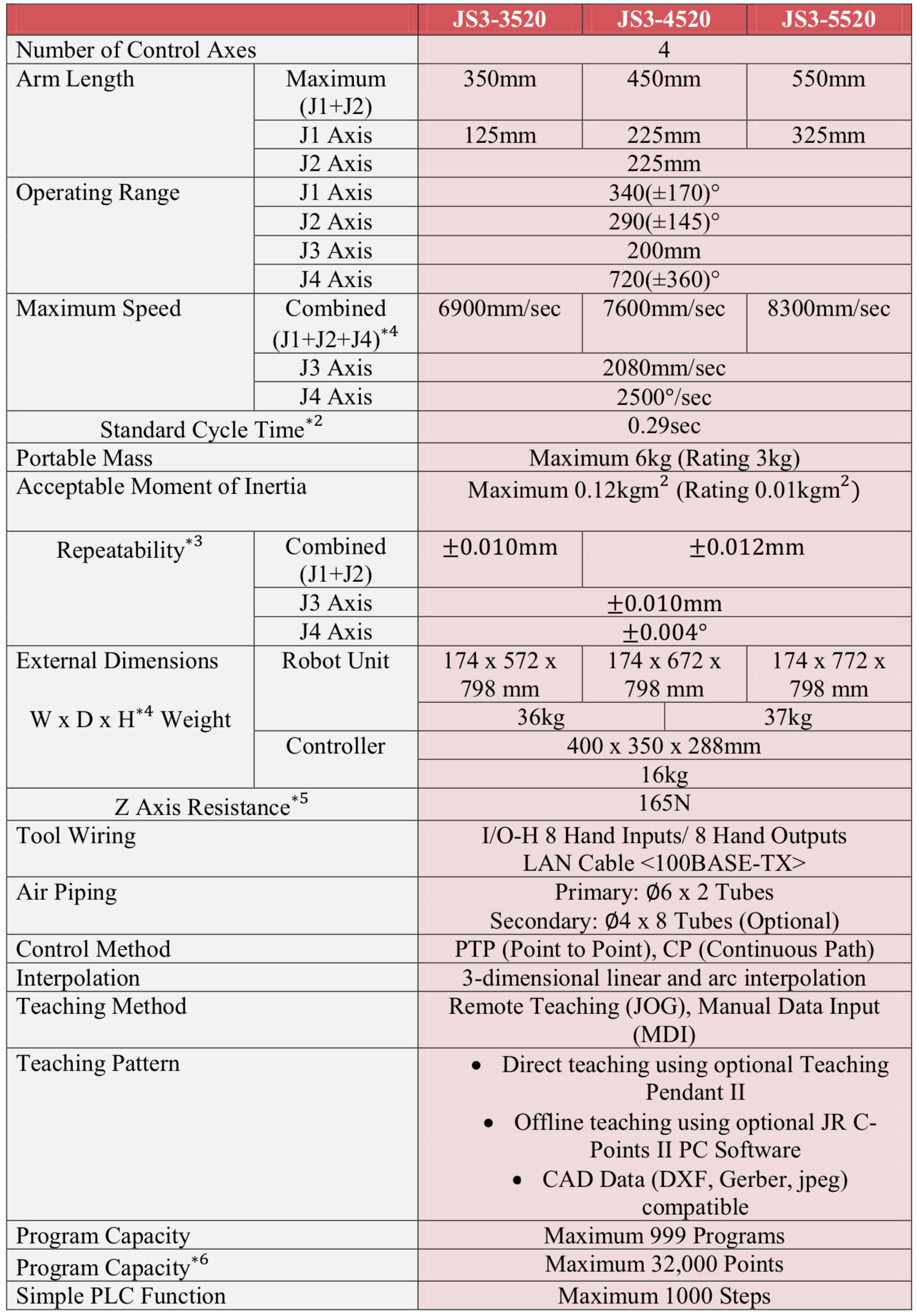

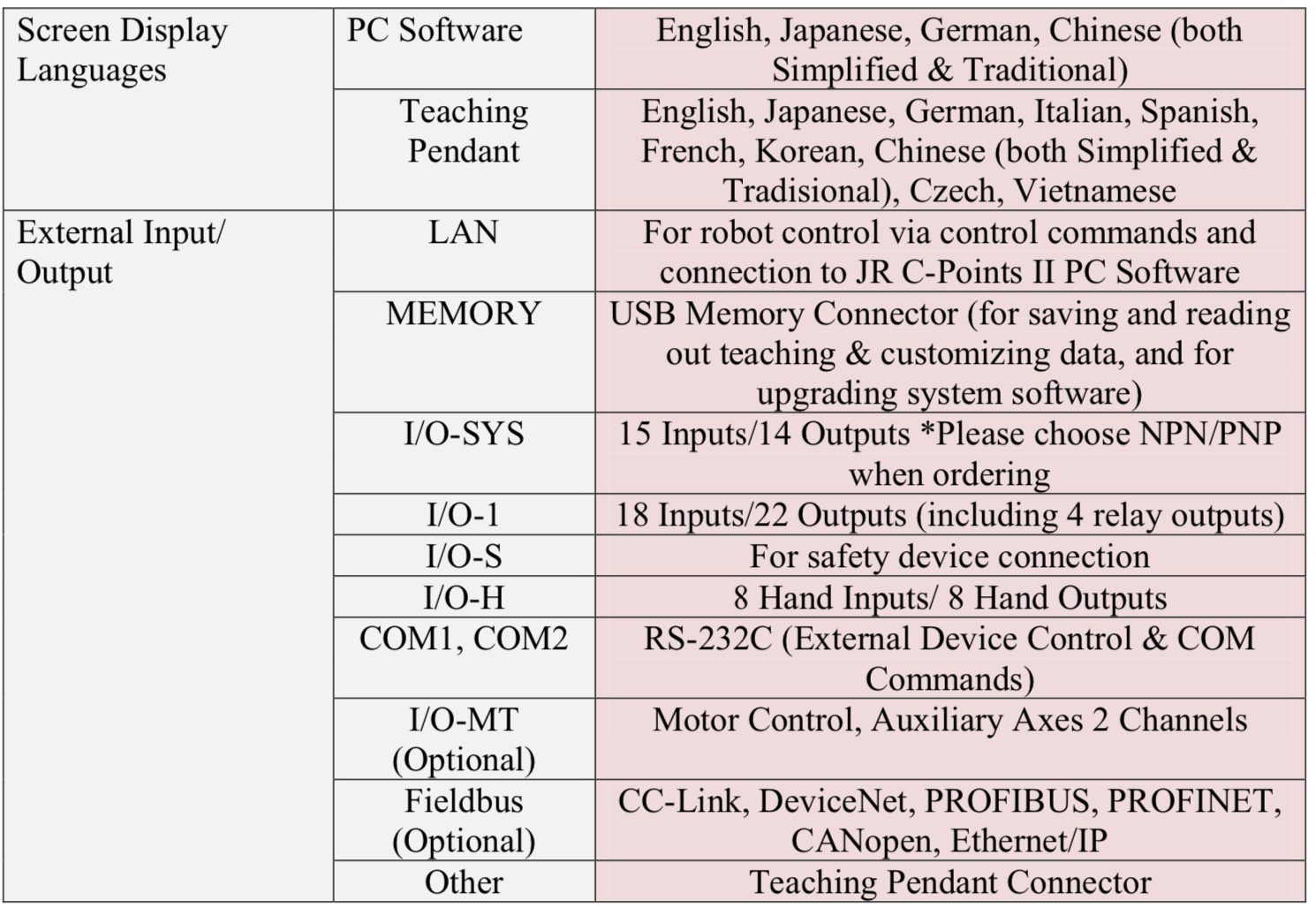

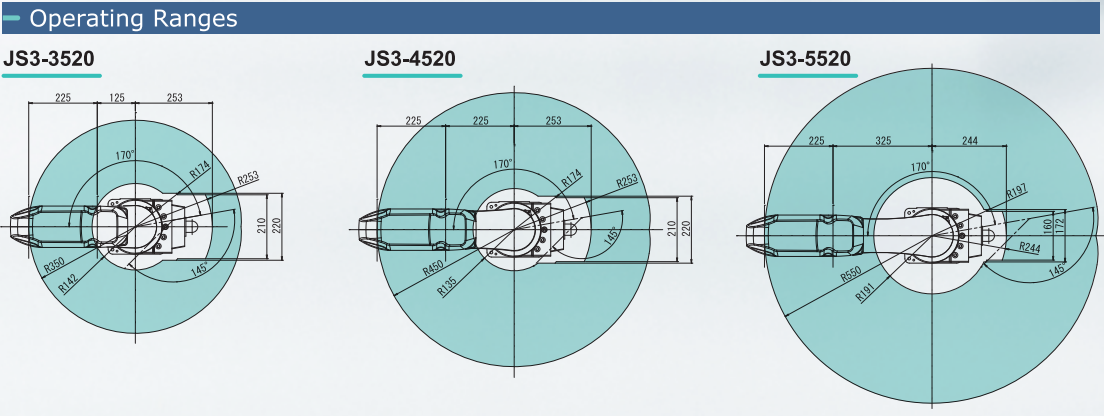

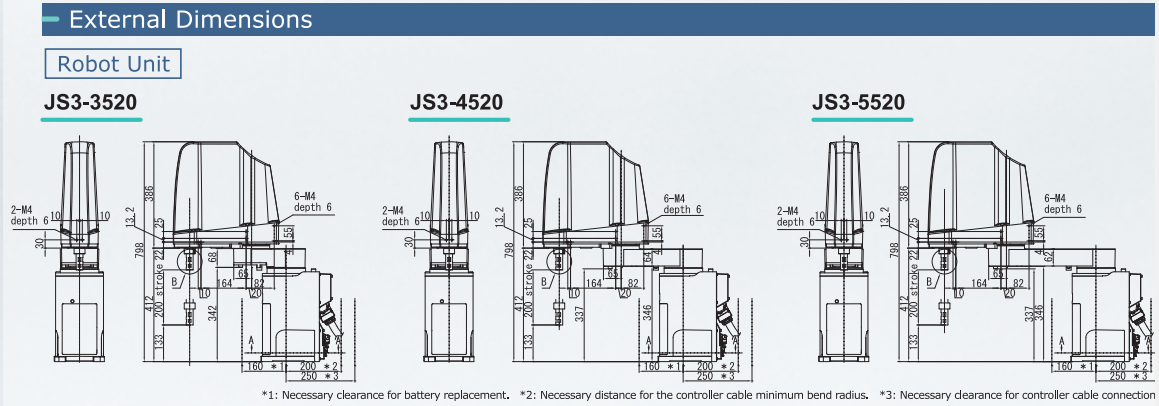

JS3 SERIES SERVO SCARA ROBOT

Highly rigid SCARA robot arm offers high speed, high precision and heavy payload capabilities! Using Janome own easy-to-use teaching software, make fine adjustments while the robot runs. Setup is simple, and the JS3 is useful for a wide range of jobs, from high-speed small parts pick-and-place transport to high-precision assembly.

Features

- User Friendly Teaching

- Works Fast

- Cable Interference Prevention

- Abundant Communication Functions

- Build-in Simple PLC Function

**Specifications may be modified without prior notice to improve product quality.