Semiconductor Industrial Solution

FUTURE TECH delivers an integrated system that enhances assembly processes with guided sequencing, built-in quality criteria, and complete traceability records to ensure consistent and reliable production.

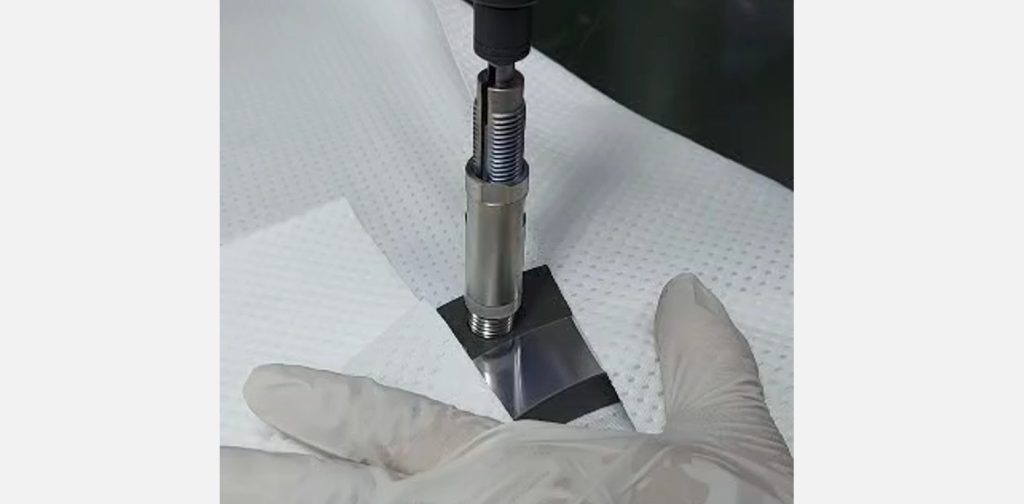

Pre-Assembly — Helical Thread Insert

Helical insert processes are prone to issues including missing inserts, prolonged cycle times, and wrong insert selection. Our engineered solutions eliminate these risks by delivering controlled, efficient, and error-proof insertion for reliable production.

Features

- Detection of missing helical thread.

- Reduction on cycle time.

- Operator guidance system.

Final Assembly — Joint Fastened

We deliver integrated assembly solutions with flexible connectivity to boost productivity, traceability, and process control—powered by Tensor IxB for error-free tightening and seamless production.

Features

- Torque accuracy with ±5.0% or ±3.5%.

- Wireless connectivity with embedded controller.

- Deliver quality joint during fastening process.

- Providing more accessible and ergonomic approach

Station Controlled System

Operator Guidance System provides step-by-step visual and digital instructions that guide operators through each assembly process, ensuring correct execution, reduced errors, and consistent production quality.

Features

- Step-by-step work instructions.

- Error-proofing system.

- Traceability and data logging.

- Reduction on training time.

- Integration with Tools and I/O devices.