General Overview

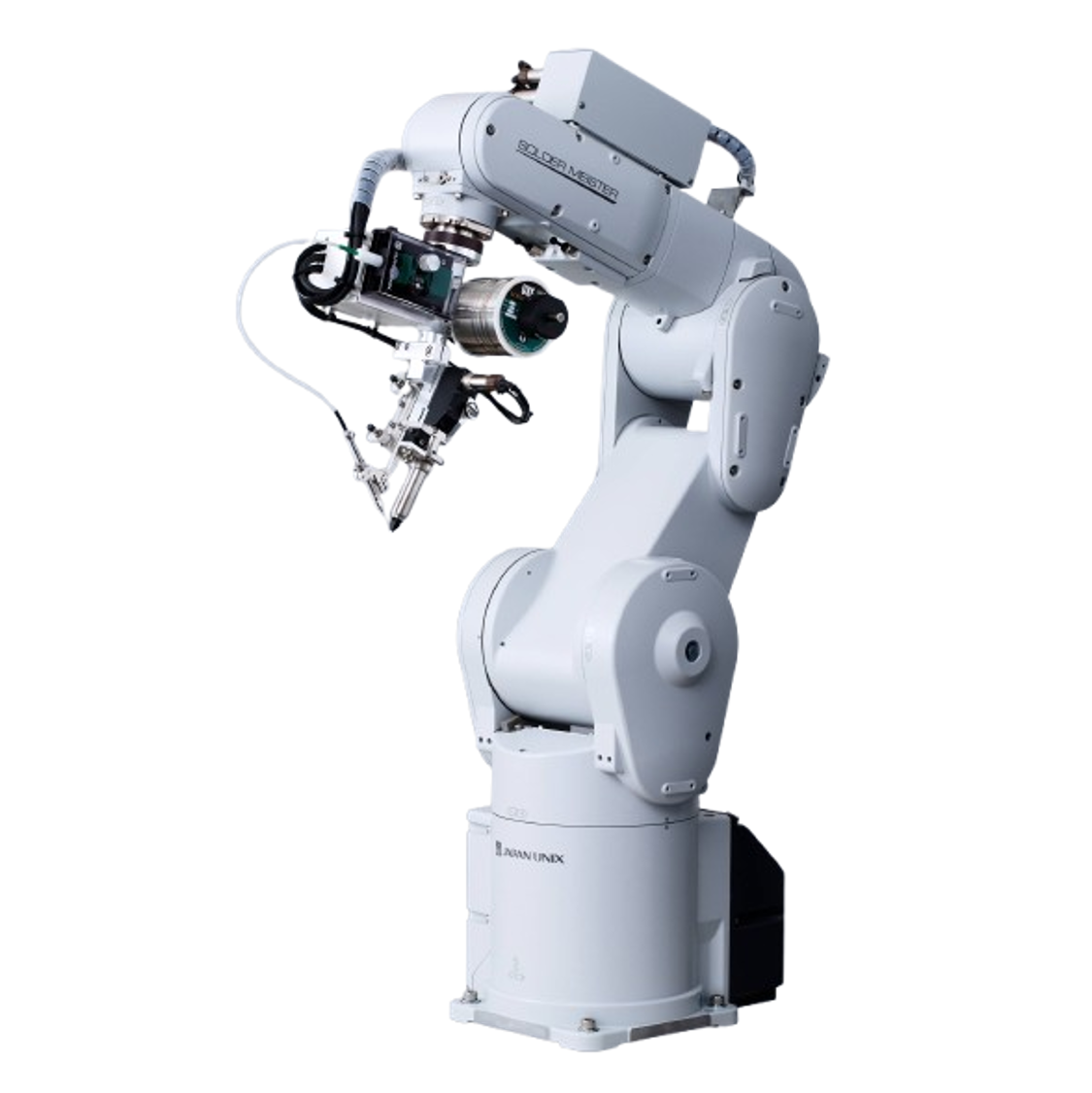

Built for versatility and efficiency, the UNIX-FR robot leverages a vertical multi-joint design to handle soldering in three-dimensional spaces with ease. Its advanced communication and software capabilities make programming, monitoring, and traceability intuitive—regardless of operator skill level. Whether integrated into an inline system or standalone workstation, the UNIX-FR enhances manufacturing performance while supporting Industry 4.0 connectivity.

Features

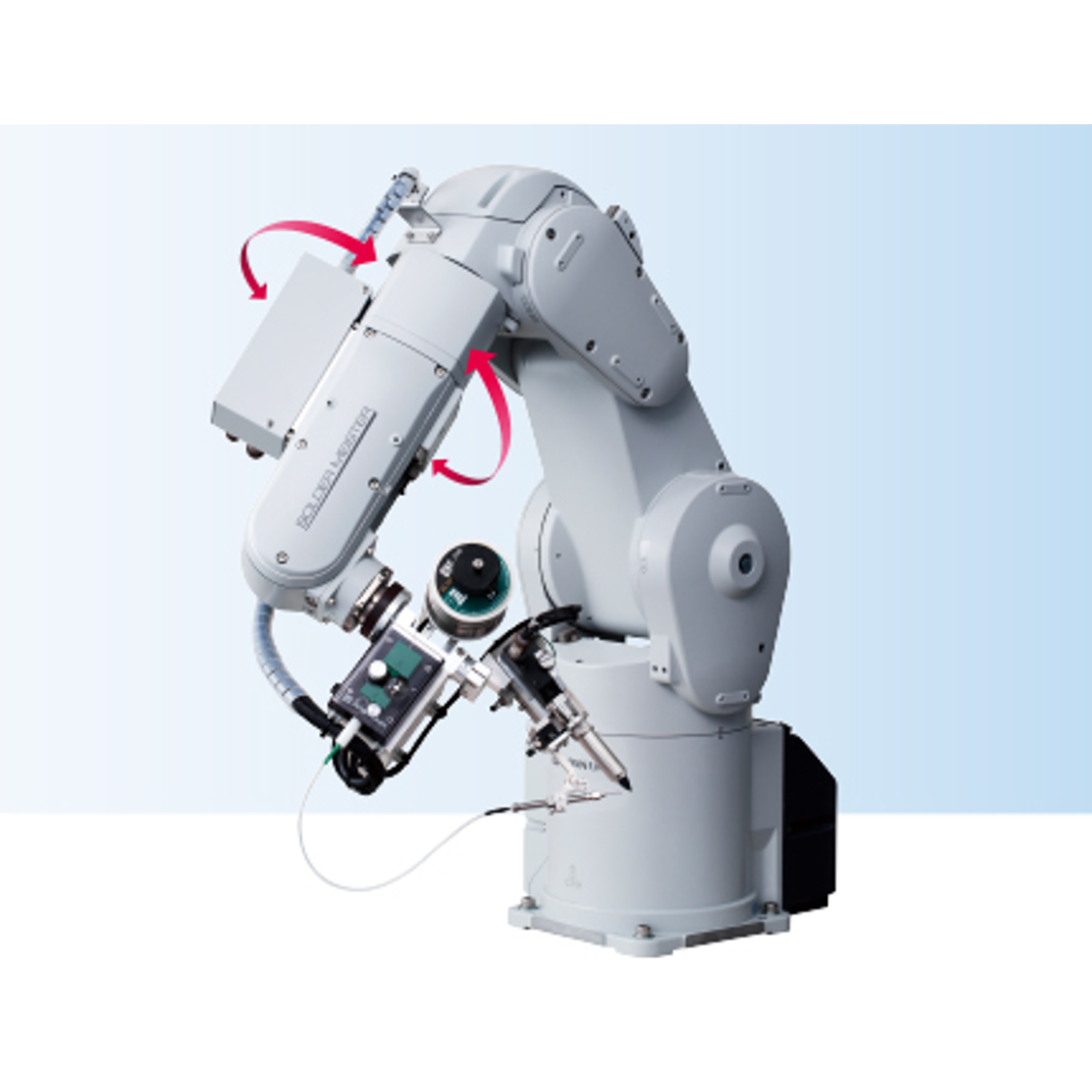

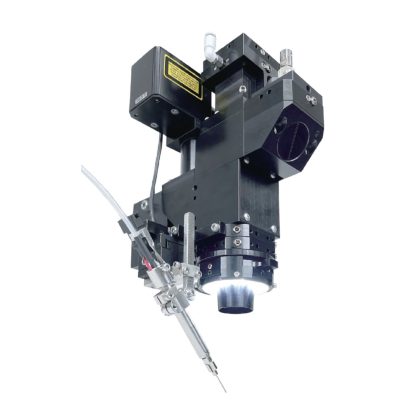

- True 3D Flexibility: Thanks to its vertical articulated structure, the robot can access soldering points on horizontal and angled surfaces with optimal tip orientation, broadening its application scope and boosting process adaptability.

- Space-Efficient Design: The compact robot footprint and motion characteristics help reduce installation space requirements compared with traditional horizontal multi-joint systems—making it ideal for dense production layouts.

- Advanced Software Integration: Includes Soldering Configurator M3, an intuitive PC-based tool for editing and storing soldering conditions, enabling easy program setup and revisions without extensive training.

- Real-Time Monitoring & Traceability: With Soldering Manager for FR, you can monitor soldering operations live and record production data for traceability. Optional cameras and barcode/2D code reading enhance tracking and quality control.

- Industrial Connectivity: Supports Ethernet and Industrial Ethernet (Ethernet/IP), allowing external condition adjustments and seamless integration with automated production systems for enhanced automation and data communication.